PLASTICS

In the delicate environment where plastics are formed, extraordinary care is essential during the definitive shaping process. The heat, chemicals, injection, and hardening elements require a surface that is extremely temperature tolerant yet dimensionally stable, resistant to residues and with a quality release that minimizes production interruptions. FIBERFLON Belting, Sheets and Adhesives are the industry highest standard resource solution.

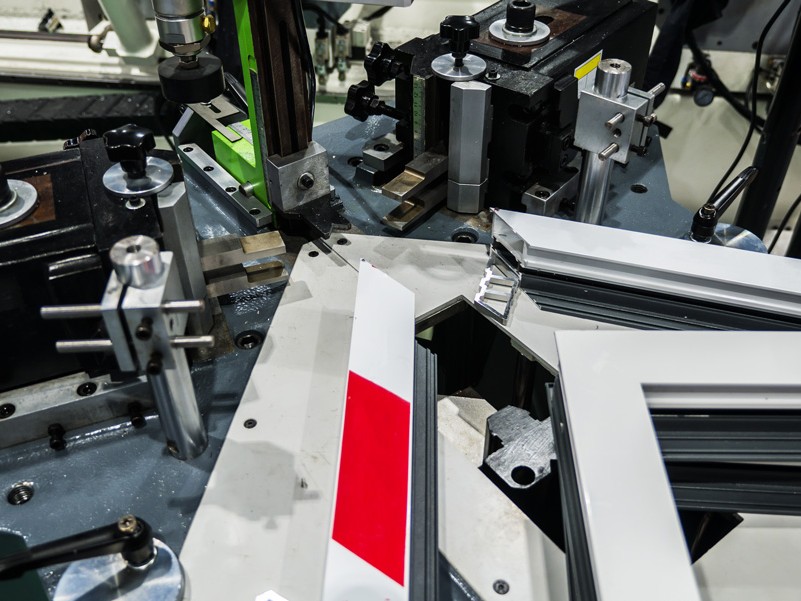

PVC WINDOWS & DOORS

Our PTFE Coated and Laminated Fabrics or Tapes are ideal as release sheets, tapes, or sleeves to cover the corner welding platens that use melted PVC to make a joint weld on one, two, or four-point welders. The quick releasing non-stick surface and high temperature tolerance prevent the PVC from residual sticking on to the welding plate.

Products of ChoicePTFE COATED FABRICS 216.15, 116.15, 116.15 GOLDPTFE LAMINATED FABRICS FIBERLAM RR15, FIBERLAM RB18, FIBERLAM 235PTFE TAPES 216.15 AD, 116.15 GOLD AD, FIBERLAM RR15 AD, FIBERLAM 235 AD

FOAM PRODUCTION & CURING

As the soft polymers are expanding into fullness, their belting conveyance–while the temperature changes in the curing process–requires the most static surface that can unaffectedly handle refining. Our belting solutions do just that with an easy no-stick release.

RUBBER CASTING & CURING

Similarly in rubber casting and curing, the injection of temperature or chemical affected molded components needs a stable easy to release surface that can handle the complex process without affecting the integrity of the output.

Relevant Brochures

PLASTIC INDUSTRY BROCHURES

Your Success is Our Success

We recognize that every customer’s needs are unique as it is with each manufacturing process. The most essential key to our success is collaborative partnership with our customers. We believe working with our customers on a close basis help us understand the specific needs of their manufacturing processes and implement accurate products to maximize productivity and minimize down-time.