Energy

FIBERFLON® products create solutions to variety of applications in the energy industry. Our PTFE composites are used to manufacture flexible fabric expansion joints, floating roof seals, wind turbine blades, photovoltaic cells, insulation covers and many more. Excellent non-stick properties, chemical inertness, high-temperature resistance, superior barrier to gas, fluids or resins are among many other significant properties of FIBERFLON® PTFE composites. The unique properties of FIBERFLON® materials allow our product line to be widely preferred by many in the energy industry.

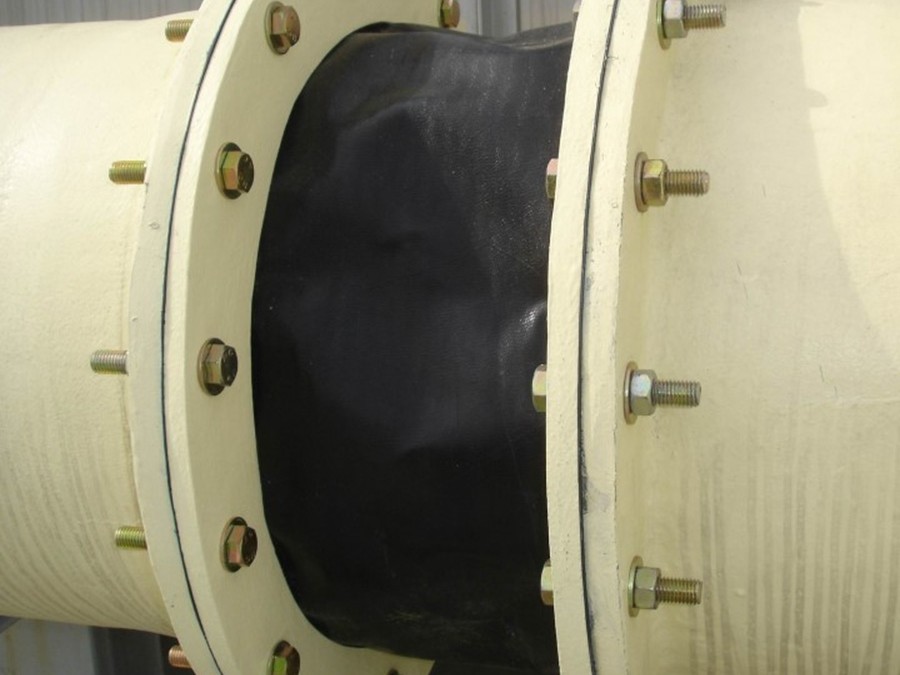

NON-METALLIC EXPANSION JOINTS

Fiberflon PTFE composites are used to manufacture flexible fabric expansion joints. These products are engineered to tolerate corrosive environments and chemical attacks while compensating for the movement in ducting, and are designed with enhanced flexibility, maximum high temperature tolerance, vibration diffusion, and superior gas barrier properties.

Products of ChoiceFIBERLAM 2001, FIBERLAM 1001, FIBERTEX 1000, FIBERTEX 2000, FIBERLAM 510, FIBERLAM 2001GM

FLOATING ROOF SEALS

Our vapor barrier membrane fabrics are used as floating roof seals to cover petroleum storage tanks. They safely stifle emissions and therefore prevent vapors from escaping into the environment.

Products of Choice628.25 AS, FRS16AS, FRS10AS

WIND BLADE MOULD RELEASE LINER

In the making of wind turbine blades, our superior PTFE Mold Release Tapes serve as impervious barrier protection against resin intrusion. The durable surface allows for a smooth, quality curved blade finish. The PTFE cast film is laminated in multiple layers on to the glass fabric to further expand the product life and reduce changeovers. Over 30 releases per single tape application.

Products of Choice216.15 AD, 116.15 GOLD AD, FIBERLAM RR15 AD

PHOTOVOLTAIC CELLS PRODUCTION

When solar cells are grouped together and soldered using a conductive stringer to join the wafers; it occurs over a PTFE Coated Conveyor Belt System. We perforate the belts as necessary to keep the suctioned cells stable while the stringers are attached. Our durable PTFE belting safely and efficiently supports the meticulous process.

Products of ChoiceCUSTOMIZED 2PLY BELTING MATERIALS (CONTACT US FOR MORE INFORMATION)

MODULE LAMINATION

When the cells are ready to be laminated into place, the heating and cooling that seals the wafers to the module is done with a vacuum laminating press; the surface of which is protected by FIBERFLON PTFE Coated Fabrics. The release sheet secures the bond and then withdraws from the press allowing it to easily and quickly go on to the next rigid or flexible module.

INSULATION COVERS

These are reusable insulating jackets, blankets, and removable insulation covers made of CHEMIFLEX Fluoropolymer Coated Glass Fabrics. High temperature (up to 599° Fahrenheit) tolerant and resistant to most chemicals.

Products of Choice440-1SC, 440-2SC, 440-1SC-AS, 440-2SC-AS, S-440-1S-AG, CHEMIFLEX 14

Relevant Brochures

ENERGY INDUSTRY BROCHURES

Your Success is Our Success

We recognize that every customer’s needs are unique as it is with each manufacturing process. The most essential key to our success is collaborative partnership with our customers. We believe working with our customers on a close basis help us understand the specific needs of their manufacturing processes and implement accurate products to maximize productivity and minimize down-time.