ALUMINUM CAN MANUFACTURING

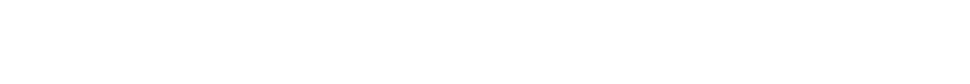

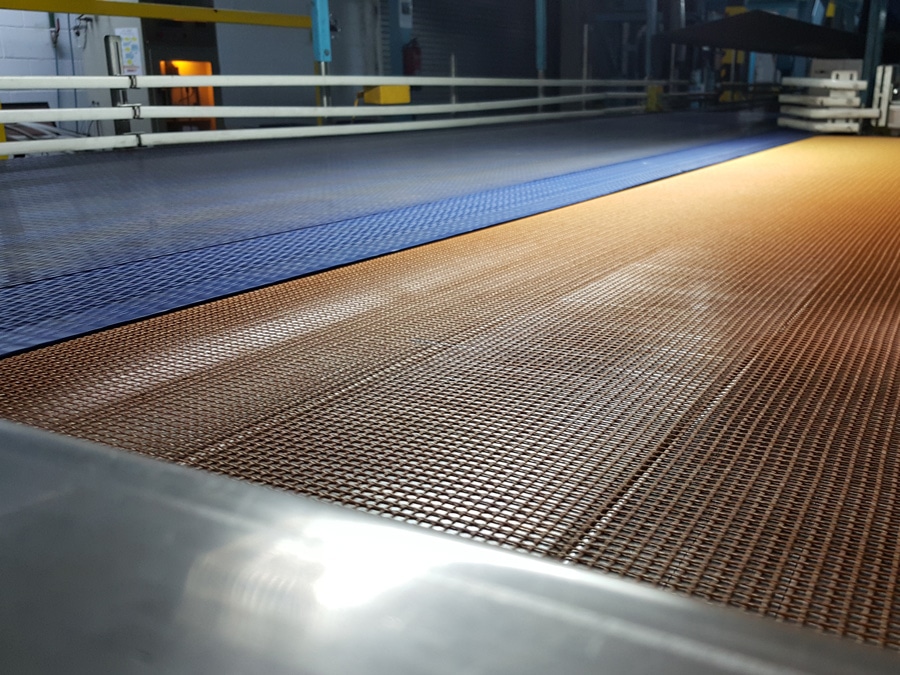

In Aluminum Can Industry, FIBERFLON® PTFE mesh belts are used in Internal Bake Ovens and Can Washer Dry Off Ovens. The interior of the cans is sprayed with an epoxy coating to prevent corrosion. Internal Bake Ovens cure the epoxy at high temperatures. Our PTFE coated mesh belting ins engineered to resist high temperatures of the process and provides airflow to aid curing. In Can Washer Dry Off Ovens, a PTFE coated Kevlar belt must be used due to its superb moisture resistance.

PTFE BELT ADVANTAGES COMPARED TO TRADITIONAL STAINLESS-STEEL CONVEYORS:

- Reduced Belt Replacement Costs

- Reduced Maintenance Costs

- Increased Energy Efficiency

- Extreme Chemical Resistance

- Less Can Tipping at Transfer Points

TYPES OF BELT SPLICES

FIBERFLON® manufactures special seams specifically made for the aluminum can industry. These belt seams are designed to reduce thickness in the seam area. The user can adjust and tighten the space between the belt and the dead plate. This eliminates the can tipping problem at the transfer points.

Relevant Brochures

ALUMINUM CAN MANUFACTURING BROCHURES

Your Success is Our Success

We recognize that every customer’s needs are unique as it is with each manufacturing process. The most essential key to our success is collaborative partnership with our customers. We believe working with our customers on a close basis help us understand the specific needs of their manufacturing processes and implement accurate products to maximize productivity and minimize down-time.